Table of Contents

In the realm of project management, staying ahead of the game is essential to drive successful outcomes. By leveraging the right methodologies, project managers can effectively organize and manage their projects while optimizing resource utilization. Two such methodologies that have gained significant traction are Lean and Six Sigma. In this article, we will explore the core principles of Lean and Six Sigma, understand their benefits, and uncover how their integration can supercharge project performance.

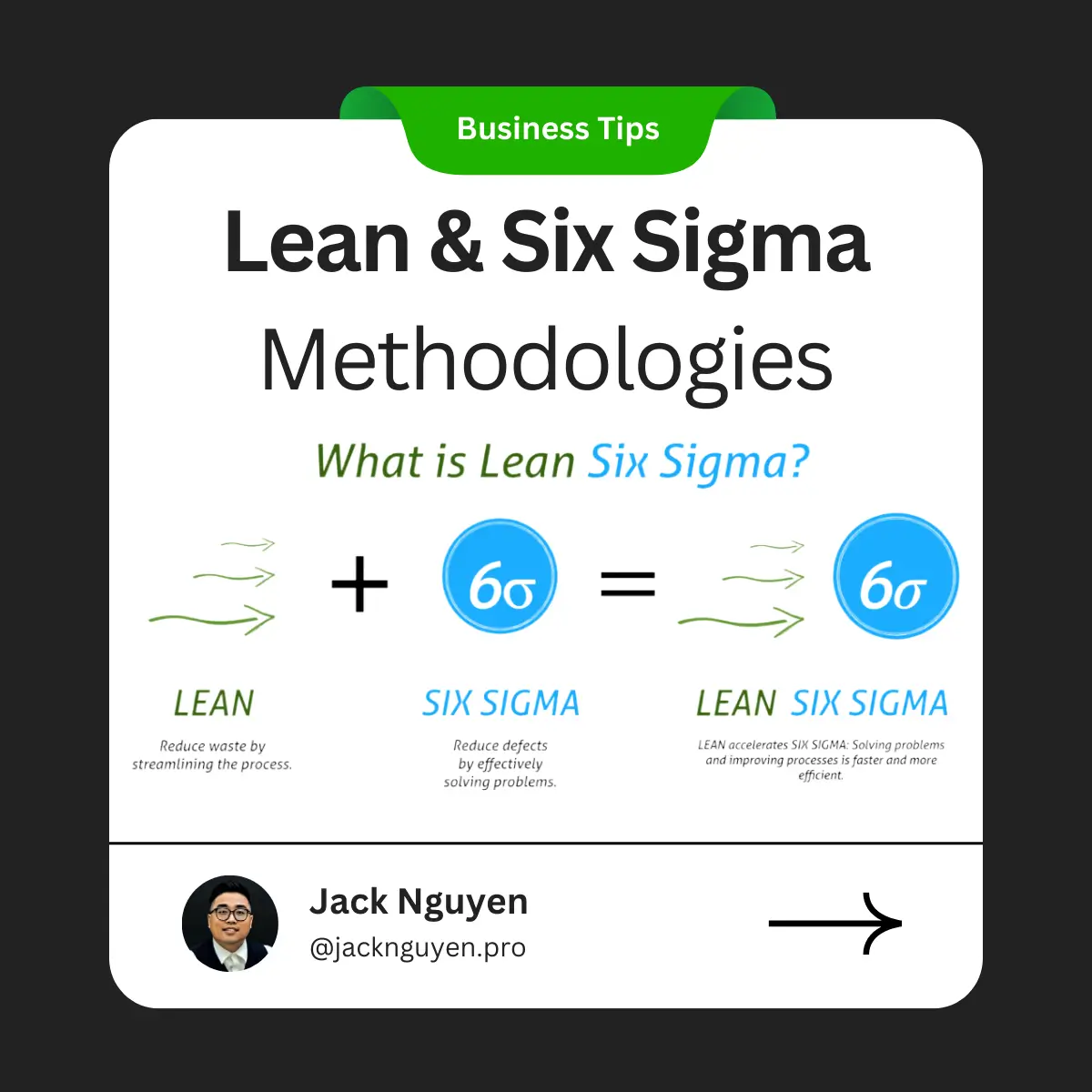

Lean and Six Sigma Methodologies

Previously, we explored the Agile and Waterfall project management approaches. Now, let us delve into the fundamental principles of Lean and Six Sigma methodologies. We will examine how these methodologies can effectively organize and manage projects and discuss their applicability to various project types.

Lean Methodology: Eliminating Waste and Adding Value

Lean methodology, often referred to as Lean Manufacturing due to its origin in the manufacturing world, focuses on eliminating waste within operations. By optimizing process steps and removing waste, value is added at each phase of production.

Presently, the Lean Manufacturing methodology recognizes eight types of waste within operations: defects, excess processing, overproduction, waiting, inventory, transportation, motion, and non-utilized talent. In the manufacturing industry, these types of waste are often attributed to issues such as:

- Insufficient documentation

- Lack of process standards

- Inadequate understanding of customer needs

- Ineffective communication

- Lack of process control

- Inefficient process design

- Failures in management

These same issues lead to waste in project management as well. Lean project management is implemented when there is a need to utilize limited resources, reduce waste, and streamline processes to maximize benefits.

To achieve this, we can employ the pillars of the Lean 5S quality tool. The term 5S refers to the five pillars necessary for maintaining a well-organized workspace: sort, set in order, shine, standardize, and sustain. Implementing the 5S method involves cleaning up and organizing the workplace to minimize wasted time and materials. The 5S method comprises the following five steps:

- Sort: Remove unnecessary items for current production operations, retaining only the essential ones.

- Set in order: Arrange necessary items in a manner that promotes ease of use. Label items to facilitate easy retrieval and storage.

- Shine: Maintain everything in the correct place and ensure a clean workspace every day.

- Standardize: Perform processes consistently using the same approach every time.

- Sustain: Develop a habit of adhering to correct procedures and instill this discipline in your team.

Within the Lean methodology, the implementation of 5S contributes to performance enhancement. Another concept within Lean methodology involves the use of a Kanban scheduling system to manage production. The Kanban scheduling system, or Kanban board, serves as a visualization tool that optimizes the flow of work within a team. It provides a visual display to identify tasks and their progress, facilitating effective coordination among team members.

Kanban boards and 5S form the core methods of Lean methodology, and their application can significantly contribute to successful project management. Now, let us analyze the Six Sigma method and determine the optimal situations for its use.

Six Sigma Methodology: Ensuring Quality and Reducing Variations

Six Sigma is a methodology employed to reduce variations by ensuring the consistent implementation of quality processes. The term “Six Sigma” originates from statistics and generally indicates that items or processes should aim for 99.9996% quality.

The Six Sigma methodology is based on seven key principles:

- Always focus on the customer.

- Identify and understand how the work gets done, gaining a deep comprehension of the actual work processes.

- Ensure smooth process flow.

- Concentrate on reducing waste and emphasizing value.

- Eliminate defects by minimizing variation.

- Involve and collaborate with the team.

- Approach improvement activities in a systematic manner.

This methodology is particularly useful when identifying measurable aspects of products or processes, such as time, cost, or quantity. By examining these measurable items, any products that fail to meet the Six Sigma standard can be rejected. Processes that produce unacceptable products must be improved upon.

Now that we have a grasp of both Lean and Six Sigma, let us explore how these methodologies can be integrated to enhance project performance.

Lean Six Sigma

After both Lean and Six Sigma were put into practice, it was discovered that combining the two methodologies could yield increased benefits. The tools utilized in Lean, such as Kanban boards and 5S, lay the foundation for building quality into processes from the very beginning. Products developed using Lean methods are then subjected to inspection or testing based on Six Sigma standards. Any products that do not meet these rigorous standards are rejected.

The primary distinction between these methodologies lies in their focus: Lean streamlines processes, while Six Sigma reduces variation in products by embedding quality from the outset and conducting thorough product inspections. Depending on the specific project requirements, you may find that implementing either one of these methods independently or integrating them together can significantly enhance project efficiency.

By leveraging the strengths of Lean and Six Sigma, you can foster a culture of continuous improvement within your project environment. Through waste reduction, process optimization, and stringent quality control, you will be better equipped to deliver high-quality outcomes while maximizing resource utilization.

Key takeaway

Remember, the success of project management lies not only in choosing the right methodologies but also in adapting and customizing them to suit the unique needs and challenges of your projects. Strive for a holistic approach that combines best practices, embraces feedback and collaboration, and continuously seeks opportunities for improvement.

Topics

Don’t forget to share this post!

Jack Nguyen

The Tech-Savvy Solopreneur

Leave a Replay

Search

About Me

Jack Nguyen is a highly experienced business coach with a proven track record of helping entrepreneurs and small business owners achieve their goals.

Recent Posts

Follow Us

Weekly Tutorial

Play Video

Copyright © 2023. All rights reserved.